Eliminator HD5

Heavy 5-axis CNC Machining

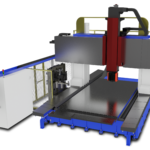

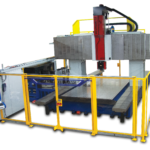

ELIMINATOR HD 5 UNIVERSAL MACHINING CENTER

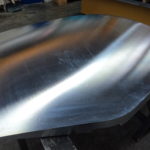

Engineered using advanced FEA methods to construct the most robust components, the HD5 5-axis machining center is built to deliver. With high speed and high torque spindles available, the HD5 can tackle project. With optional high gap longer X and Y travels, and higher power spindles, there is a machine configuration for any large part machining requirement.

- Travel: 180” – 834” X Axis, 60” – 200” Y Axis, 22” Z Axis

- Spindle Speed – 0 – 24,000 rpm

- Extremely rigid structure

- High Torque and High Power spindle options

- Large capacity ATC available

Applications

- Aerospace

- Defense

- Mold & Die

- Marine

- Job Shop

Specifications

| Capacity | ||

|---|---|---|

| X-axis | 180 - 220" | 4,572 - 5,588 mm |

| Y axis | 60-200" | 1,524 - 2,438 mm |

| Z axis | 44" | 1,118 mm |

| Bridge gap | 48 - 60" | 1,219 - 1,524 mm |

| Longer axes strokes available | ✓ | |

| Spindle | ||

| Speed | 7,000 - 24,000 rpm | |

| Power S1 | 54 - 117 hp | 40 - 87 kW |

| Torque S1 | 30 - 370 ft-lb | 48- 500 Nm |

| Taper | HSK63 / HSK100 | |

| Type | Electrospindle | |

| Feed | ||

| Max Feed | 720 ipm | 18 m/min |

| Max Rapid | 800 ipm | 20 m/min |

| Max Acceleration | 0.226 g | 2.2 m/s2 |

| Accuracy | ||

| Standard | Per ISO 230-2 | |

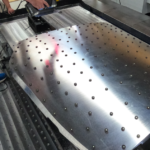

| Coolant | ||

| Flood | ✓ | |

| Through Spindle | ✓ | |

| Programmable Coolant | ✓ | |

| Standard coolant system | 250 psi / 10 gpm | 17 bar / 38 lpm |

| Optional HP System | 1,000 psi / 15 gpm | 70 bar / 60 lpm |

| Tank capacity | 177 galm | 673 L |

| Control | ||

| CNC System | Fanuc or Siemens |

Additional power, sizes, features and accessories are available.

Quickmill is recognized as a Fanuc Authorized CNC Integrator. We are proud to work with Fanuc America to identify and implement best-in-class practices for CNC integration on our machines.

Quickmill is recognized as a Fanuc Authorized CNC Integrator. We are proud to work with Fanuc America to identify and implement best-in-class practices for CNC integration on our machines.REQUEST A QUOTE

Smart Machining Starts with Smart Conversations

If you are looking to increase your throughput, maximize floorspace or address other industrial machining solutions let’s talk about how a Quickmill machining center can help.