FRICTION STIR WELDING SYSTEMS

Precision. Power. Process-Driven Reliability.

Transform the way you weld.

Quickmill’s Friction Stir Welding Machines bring unmatched rigidity, intelligent control, and scalable performance to the industries that demand the strongest, cleanest, and most consistent welds in the world.

FSW Built for Production, Not Compromise

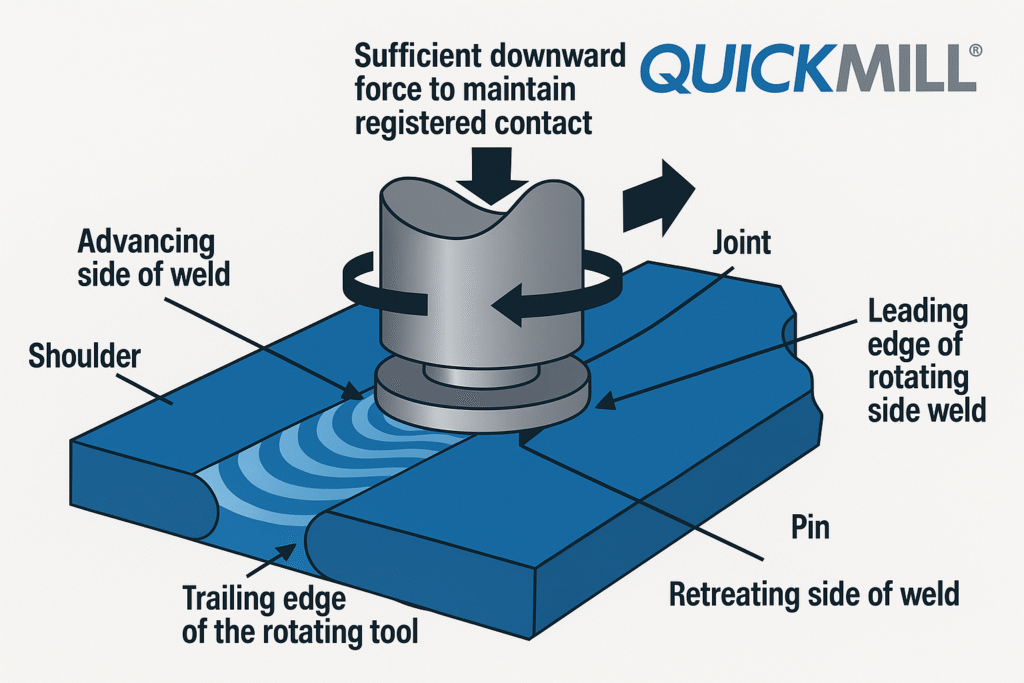

Friction Stir Welding has earned its place as the go-to solid-state joining method for aluminum and other soft metals. It produces stronger welds, eliminates porosity and cracking, and dramatically reduces distortion. But to achieve those results at scale, you need more than a spindle and a tool—you need a machine engineered for the forces involved.

Quickmill’s FSW platform is built on our proven large-gantry CNC architecture, combining powerful thrust capacity, exceptional stiffness, and advanced process intelligence. The result: a machine that makes friction stir welding not just possible, but repeatable, traceable, and ready for 24/7 manufacturing.

WHY FRICTION STIR WELDING?

High-Strength, Defect-Free Joints

Solid-state welding eliminates melting, reducing porosity, cracking, and metallurgical weakness.

Low Distortion, High Precision

Minimal heat input means cleaner, more dimensionally stable parts—ideal for precision assemblies.

Environmentally Friendly

No filler metal. No fumes. Lower energy usage than traditional welding.

Design Freedom

Join complex shapes, long seams, dissimilar alloys, and large structural components with ease.

WHY QUICKMILL FOR FSW?

Where Machine Tool Engineering Meets Advanced Welding Technology

Extreme Machine Rigidity

FSW demands enormous axial force and unwavering stability—especially across long travels. Quickmill machines are engineered from the ground up to handle these loads, delivering consistent forging pressure for defect-free welds.

High-Torque, High-Thrust Spindle Systems

Purpose-built spindle solutions allow for deep penetration and robust material mixing while maintaining smooth, controlled rotation.

Intelligent Process Monitoring + Real-Time Adaptation

Using advanced sensors, thermal data, and machine feedback, the system can detect developing defects and automatically adjust parameters—reducing scrap and improving overall weld quality.

Large-Format Capability

Rail car components, aerospace panels, plate cooling panels and heat exchangers, EV structures, marine panels—you name it. Quickmill’s large travels give manufacturers the ability to weld big components in a single setup.

Designed for Production Environments

Low maintenance requirements, proven CNC architecture, and fully integrated automation make Quickmill FSW machines ideal for high-duty-cycle operations.

TECHNOLOGY OVERVIEW

Solid-State Welding Expertise Our system uses controlled axial force, precise tool plunge, and active feedback loops to ensure consistent weld penetration and material flow.

Tooling Compatibility Compatible with industry-standard FSW tools, including fixed-pin, retractable-pin, and self-reacting designs.

Welding Modes Supported

Conventional FSW

Self-Reacting FSW

Spot and stitch welding

Single- or multi-pass welds

Force-controlled and position-controlled modes

APPLICATIONS

Aerospace

Long, lightweight structural panels, rib-to-skin joints, stiffeners, cryogenic tanks.

Automotive & EV

Battery trays, knuckles, sub-assemblies, crash structures.

Rail & Transportation

Large extruded panels, floor structures, frame components.

Energy

Heat exchangers, aluminum plate structures, pressure panels.

Marine

Hull panels, deck components, corrosion-resistant assemblies.

TECHNICAL SPECIFICATIONS

(Example—can customize once you provide your actual numbers)

X-Travel: Up to 40 ft (72m for inc scales from Heidenhain)

Y-Travel: Up to 20 ft (7m seems to be the upper limit from OEMs)

Z-Travel: Up to 48 in (1.5m max)

Axial Force Capacity: 20–150 kN (per requirements)

Spindle Power: 30–80 hp high-torque options ( up to 100hp) (or up to 134hp high speed spindles)

Max Spindle Speed: 4,000 RPM (30,000rpm available for milling)

Path Accuracy: ±0.001–0.002” in depending on configuration

Automation Options: Tool changers, probing, 3d scanning, temperature monitoring, robotics integration

THE QUICKMILL DIFFERENCE

Engineering First

Every FSW solution is custom-engineered to the application—not forced to fit a template.

Massive Machine Structures

Minimizes deflection, chatter, and thermal drift for consistent weld quality.

Support You Can Count On

From process development to installation to on-site training, Quickmill’s team is with you at every stage.

Future-Ready Architecture

Integrated sensor ports, real-time analytics, and AI-ready data pipelines open the door for next-generation adaptive welding.

Want to See What Quickmill FSW Can Do for Your Application?